We aim to fix your boiler on our first visit. Our engineers always carry a wide range of parts and tools, we’ll do our best to have you up and running in a timely and convenient manner.

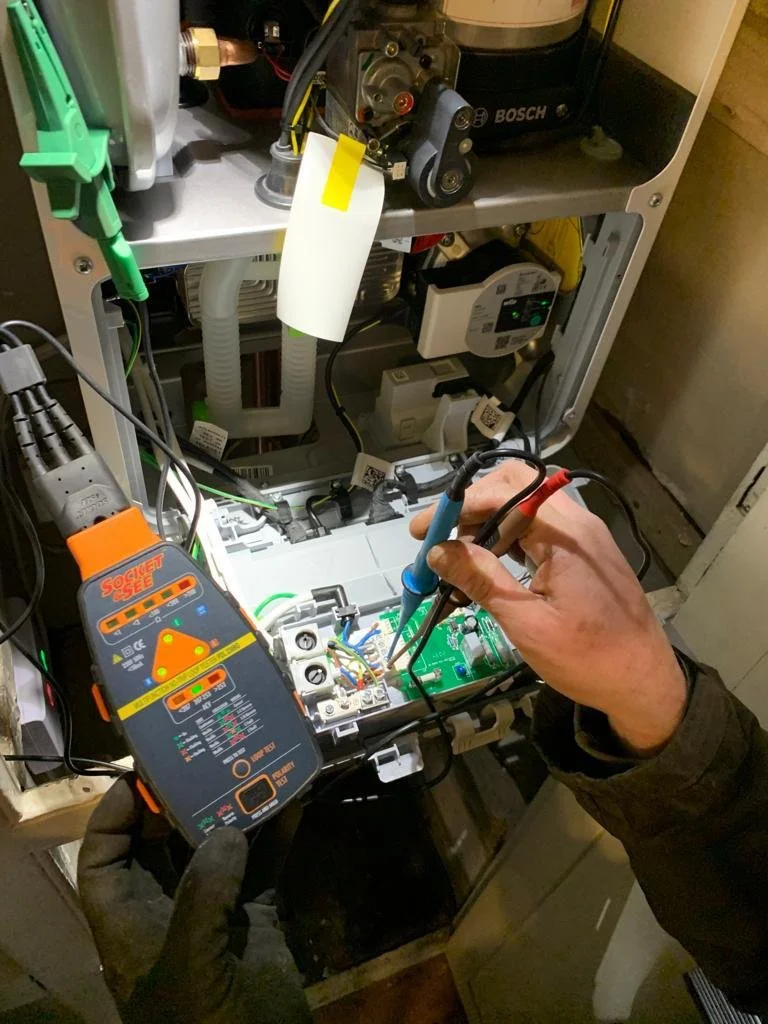

Consultation and diagnostics

Over 70 percent of visits we can repair your boiler in the first visit. However, sometimes we need to obtain specific parts, and, in this case, we will do our best to give you a price and lead time before our engineer leaves. Some jobs will also require a longer time frame so we will work with you to pick a convenient time to return and complete the work.

Parts supply/ fitting and testing

Our boiler repairs come fully warranted, and with a wealth of experience, our engineers are able to complete the job in a quick, safe, and convenient manner. Fully certified we can work on all gas boilers.

Aftercare and guidance

No matter the repair we will leave your appliance working efficiently and safely. Any appliance worked on will be safety checked to governing procedures. Our engineer can easily be contacted once the job has been completed for any guidance relating to the repair.

Commonly replaced parts

These are the most commonly replaced parts. Depending on your boiler the times given can vary.

PCB 1-2 hours - As the boiler’s nerve centre the PCB controls every electrical component, ranging from the fan to the LED screen. The solder that holds the circuit board together can deteriorate over time, damage can occur from leaking water, and cracks or fractures aren’t unheard of either.

Heat exchangers 2-5 hours - Exposed to water the heat exchanger is susceptible to the build-up of limescale or sludge within the system. In unfortunate circumstances, this can have the potential to harm the heat exchanger. The heat exchanger cannot be fixed and will have to be replaced. It’s always good to protect the components of your boiler by fitting prevention devices.

Automatic air vents (AAV) 1-2 hours - AAV are used to release any air in your system. They are susceptible to blockages due to sludge or another build-up. Generally an easy replacement it’s a good idea to have another one somewhere in your system.

Fans 1-2 hours - Probably the most used component within your boiler. The fan is used to eject waste gases via the flue. Bearings and speed controllers are known to fail.

Gas valves 1-2 hours - The gas valve controls the amount of gas flowing to the flame. A working gas valve is crucial to a boiler’s safe operation, generally an easy part to get hold of as they tend to fail over time.

Expansion vessels 1-3 hours - The expansion of water when It heats is a familiar concept. As the boiler heats up, water flows into the expansion vessel to prevent any damage to other components. Like any component exposed to water, dirty systems can cause corrosion and build-up within the expansion vessel.

Diverter Valves - 1-2 hours - The diverter valve does exactly what it says, it will either circulate hot water around your heating system or to your hot tap. They commonly seize due to corrosion and sometimes can be cleaned but are commonly replaced.

Pressure relief safety valves 1-4 hours - A pressure relief valve prevents your boiler from being over-pressurised, causing a safety risk. After a good number of years, they can become faulty, thus why a service is very important.

Ensure you have your boiler serviced every year, our engineers are trained to spot failing parts and prevent a costly breakdown.

For diagnostics we charge 75+ Vat per hour. Each repair your will be quoted a price for the whole job, at 65+ vat per hour plus materials.